Had a productive weekend and removed the drivetrain despite the 101°F heat index (!). I put the chassis on wheel dollies and tucked it away in front of the other two cars. It’s not exactly easy to get to, but it’s easier than it being outside.

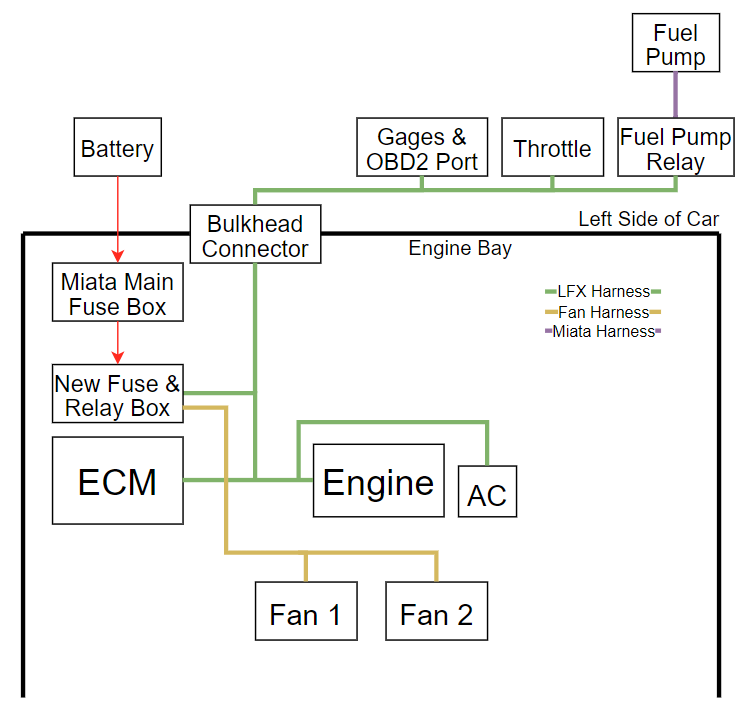

In parallel I’ve been working on the wiring – I’m starting with a high level block diagram, now on revision 3:

There are three functions where the Miata and new harnesses interface:

- Fuel pump

- AC compressor

- Fans

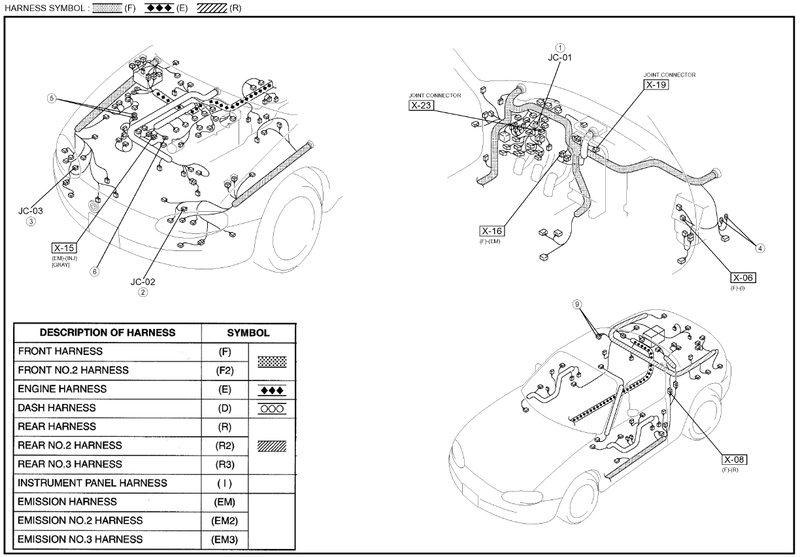

Fortunately there is an emissions connector in the Miata harness, x-16, where the AC “command compressor on” signal and fuel pump relay coil are present. Ideally I’ll be able to connect my interior harness to this connector and avoid splicing into the Miata harness. Obviously I’ll be modifying it pretty significantly anyways, but it should draw a clean line between the two systems.

The Miata PCM grounds the fuel pump relay to enable it, and the other side of the coil is connected to switched power through the main relay. The e39 uses a return-less system and controls the fuel pump speed via a PWM signal to the fuel pump control module. I should be able to re-use the stock Miata fuel pump relay by connecting the non-x-16 side of the relay coil to ground and connecting the e39 fuel pump PWM signal to x-16. @rdb138 used this approach and it’s worked fine for him – I’ll probably add a flyback diode across the relay in case the e39 output isn’t protected.

For the AC compressor, I’ll probably take the same approach @gooflophaze did and wire up a “dumb” AC compressor control circuit. I looked into using the e39 output, which would be nice since it compensates for the added load and turns the fans on, but it would require the HVAC control module or knowing what message to send the e39. Since I don’t have a Camaro, I’ll take the “dumb” approach for now. If anyone knows what message to send the e39 to turn the AC compressor on, I’m all ears 🙂

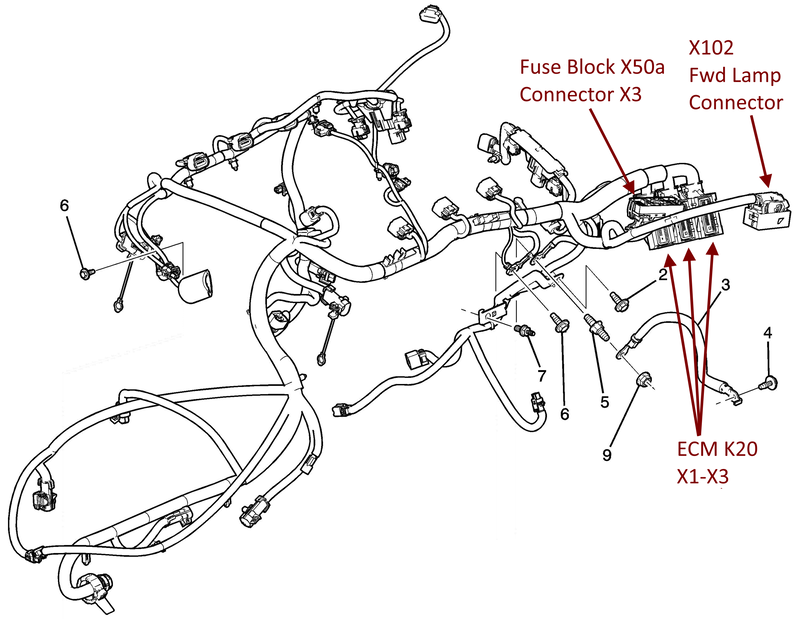

The fans are probably the easiest since the e39 has relay control outputs. Those will get wired in a low\high speed configuration similar to the Camaro.

Alternator control is another question I need to address – the e39 controls the field coil (and therefore how much voltage the alternator produces). The ECM determines how much voltage the alternator should produce based on a “battery current sensor” in the “battery housing” (according to the Camaro schematics), which I obviously won’t have. I believe @gooflophaze is working on a control module, but I don’t think it’s ready yet. Others have replaced the factory alternator with a simpler alternator, but according to gooflophaze if you just disconnect the alternator connector (not the wire) it should fall back to 13.8V. It’s not perfect, but it’s probably good enough.

I think I’ve accounted for all of the signals, so now it’s on to making schematics for each of the new harnesses and picking out connectors. I’m a little worried about putting the throttle pedal through a connector since @ThePass (and @rdb138 , I think) had issues with any sort of noise putting the ECM into “safe” mode. I’ll start out with a good, aerospace-grade connector and if I run into issues, I’ll bypass the connector and run straight from the ECM to the throttle pedal.

I’ve seen others (@griff ?) connect a flex fuel sensor into the e39 but I’m not sure where it gets connected – I’m guessing through the AC pressure sensor input?